What Kind of Motor Should I Select for Industrial Use?

Selecting the right motor for an industrial application is critical to ensuring operational efficiency, equipment longevity, and overall system performance. Motors are the driving force behind countless industrial processes, from conveyor systems and pumps to compressors and robotic automation. A properly matched motor enhances energy efficiency, reducing power consumption and operational costs, while an undersized or improperly selected motor can lead to excessive heat buildup, increased wear, and premature failure. Factors such as torque requirements, speed control, duty cycle, and environmental conditions play a crucial role in determining the best motor type—whether it’s an AC induction motor, servo motor, or a variable frequency drive (VFD)-controlled motor. Additionally, selecting the right enclosure type (e.g., TEFC, ODP, or explosion-proof) ensures protection against contaminants, moisture, and hazardous environments. A well-chosen motor not only optimizes performance and reliability but also minimizes unplanned downtime and maintenance costs, leading to a more productive and cost-effective industrial operation.

Shop Our Industrial Motors

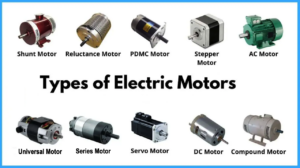

Different Types of Motors

AC Motors

Characteristics of AC Motors

AC (alternating current) motors are the workhorses of industrial automation, known for their reliability, efficiency, and adaptability across various applications. They operate using an AC power source, and their speed is typically controlled by the supply frequency or variable frequency drives (VFDs). AC motors can be classified into induction motors (squirrel cage and wound rotor) and synchronous motors, each with unique characteristics suited for different operational needs. Induction motors are widely used due to their rugged design, self-starting capability, and low maintenance, whereas synchronous motors are preferred for applications requiring precise speed control and high power factor efficiency.

Advantages of AC Motors

- High Efficiency & Energy Savings – Modern AC motors, especially those designed to IE3 and IE4 efficiency standards, offer excellent energy savings and reduced operational costs.

- Low Maintenance – With fewer moving parts compared to DC motors, AC motors require minimal maintenance, making them ideal for continuous operation.

- Scalability & Power Range – Available in power ratings from fractional horsepower (HP) to several megawatts, they can accommodate a wide range of industrial applications.

- Compatibility with VFDs – Variable frequency drives (VFDs) allow for precise speed and torque control, enhancing motor efficiency and extending equipment lifespan.

- Durability in Harsh Environments – AC motors are available in TEFC (totally enclosed fan-cooled), ODP (open drip-proof), explosion-proof, and washdown enclosures, making them suitable for extreme conditions such as high heat, moisture, dust, and corrosive environments.

Typical Industrial Applications of AC Motors

- Pumps & Fans – Used in HVAC, water treatment, and cooling tower systems.

- Conveyors & Material Handling – Found in warehouses, logistics centers, and manufacturing plants.

- Compressors – Common in refrigeration, air compression, and gas processing industries.

- Mixers & Agitators – Utilized in food processing, chemical manufacturing, and pharmaceutical production.

- CNC Machines & Robotics – High-precision applications requiring synchronous AC motors for precise motion control.

- Heavy-Duty Industrial Machinery – Found in mining, steel mills, and oil & gas applications where high torque and robust performance are essential.

Popular AC Motor Brands in the Market

Several manufacturers dominate the AC motor market, providing high-quality solutions for industrial applications:

- Siemens – Known for energy-efficient motors, industrial automation integration, and VFD compatibility.

- ABB (Baldor-Reliance) – Offers a wide range of high-efficiency motors, including explosion-proof and washdown-rated options.

- WEG – Recognized for durable and high-performance motors, particularly in energy-intensive industries.

- Toshiba – Specializes in heavy-duty industrial motors designed for harsh environments.

- Rockwell Automation (Allen-Bradley) – Provides integrated motor and drive solutions, particularly for automation systems.

- Nidec (U.S. Motors, Leroy-Somer, Emerson) – A global leader in AC motor technology, known for reliable and customizable designs.

DC Motors

Characteristics of DC Motors

DC (direct current) motors are widely used in industrial applications where precise speed control, high starting torque, and variable speed operation are essential. Unlike AC motors, which rely on alternating current, DC motors operate on direct current, typically supplied by batteries, rectifiers, or dedicated DC power supplies. These motors can be categorized into brushed (series, shunt, and compound wound) and brushless DC (BLDC) motors. Brushed DC motors offer simple design and cost-effective speed control but require periodic maintenance due to brush wear. Brushless DC motors (BLDC), on the other hand, use electronic commutation for longer life, higher efficiency, and reduced maintenance requirements.

Advantages of DC Motors

- Precise Speed Control – DC motors offer smooth and adjustable speed control over a wide range, making them ideal for variable-speed applications.

- High Starting Torque – They generate high initial torque, making them suitable for applications requiring rapid acceleration and heavy loads.

- Instantaneous Reversing – Unlike AC motors, which require additional circuitry for reversing, DC motors can easily change direction with simple polarity switching.

- Independent of Supply Frequency – Unlike AC motors that depend on fixed supply frequencies, DC motors can operate at precise speeds without requiring frequency converters.

- Efficient Operation in Low-Speed Applications – DC motors maintain consistent torque output at lower speeds, making them ideal for positioning and lifting applications.

Typical Industrial Applications of DC Motors

- Cranes & Hoists – Used in material handling, lifting operations, and industrial winches due to their high torque characteristics.

- Electric Vehicles (EVs) & Traction Motors – Common in forklifts, trains, mining trucks, and hybrid vehicles where controlled acceleration and regenerative braking are needed.

- Conveyor Systems – Found in packaging, food processing, and distribution centers where speed variability is required.

- Steel & Paper Mills – Utilized in rolling mills, printing presses, and machine tools that require controlled speed variations.

- Robotics & Automated Machinery – DC motors, especially BLDC motors, are used in robotic arms, CNC machines, and industrial automation systems.

- Battery-Powered Equipment – Common in off-grid applications, portable devices, and remote industrial setups.

Popular DC Motor Brands in the Market

Several manufacturers lead the DC motor industry, offering high-performance solutions for industrial applications:

- Baldor-Reliance (ABB) – Offers rugged and high-efficiency DC motors for demanding applications.

- Siemens – Provides precision-controlled DC motors used in industrial automation and traction applications.

- WEG – Specializes in DC motors for steel, mining, and crane applications, ensuring durability and efficiency.

- Leeson (Regal Beloit) – Produces durable brushed and brushless DC motors designed for conveyor systems and automation.

- Allen Bradley – The 1325 motor series works seamlessly with your automation controls rectified speed in VSD

Servo Motors

Uses of Servo Motors

Servo motors are essential in high-precision motion control applications, where accurate positioning, speed, and torque control are critical. They operate using a closed-loop feedback system, ensuring precise adjustments based on real-time sensor data. Servo motors are widely used in:

- Robotics & Automation – Enables precise movement in robotic arms, CNC machines, and pick-and-place systems.

- Packaging & Labeling Machines – Provides consistent speed and position control for automated assembly lines.

- Medical & Aerospace Equipment – Used in prosthetics, surgical robots, and aircraft control systems for precise actuation.

- Textile & Printing Machinery – Ensures high-speed, accurate fabric cutting and color registration in industrial printing.

Benefits of Servo Motors

- High Torque with Precision Control – Delivers instantaneous torque adjustments, crucial for robotics and automation.

- Closed-Loop Feedback System – Uses encoders and sensors for real-time error correction, ensuring superior accuracy.

- Fast Acceleration & Deceleration – Provides rapid response times, making it ideal for dynamic applications.

- Energy Efficiency – Operates efficiently under varying load conditions, reducing energy waste.

- Compact & Lightweight Design – Allows for easy integration into space-constrained applications.

Popular Servo Motor Brands

- Yaskawa – Known for high-performance servo solutions in factory automation and robotics.

- Mitsubishi Electric – Offers ultra-fast response servo systems with advanced tuning features.

- Siemens – Provides precision servo motors with seamless integration into industrial automation.

- Rockwell Automation (Allen-Bradley) – Specializes in motion control solutions for high-speed manufacturing.

- Fanuc – Trusted for servo motors in CNC machining, robotic systems, and automated manufacturing.

Shop Our Industrial and Commercial Servomotors

Factors in Motor Selection Guide

Load Requirements

- Determine Load Type – Identify whether the load is constant, variable, or shock (e.g., conveyors vs. crushers).

- Calculate Torque Needs – Consider starting, running, and peak torque to ensure the motor can handle required forces.

- Evaluate Speed Requirements – Match motor RPM to the application’s speed range; use VFDs or gear reductions if needed.

- Assess Duty Cycle – Determine if the motor runs continuously, intermittently, or cyclically, impacting thermal management.

- Consider Power Supply Compatibility – Ensure the motor voltage and phase (AC/DC, single/three-phase) match available power.

- Check Environmental Conditions – Select TEFC, ODP, explosion-proof, or washdown-rated motors for harsh settings.

Speed Control and Torque

- High Torque, Low Speed Applications – DC motors & gear motors are ideal for cranes, hoists, and conveyors, where starting torque is critical.

- Variable Speed & Precision – Servo motors provide precise torque and speed control, perfect for robotics, CNC machines, and automation.

- Constant Speed & Efficiency – AC induction motors are best for pumps, fans, and compressors, where steady operation is key.

- High-Speed, Low Torque – Synchronous AC motors & brushless DC motors excel in printing presses, medical devices, and textile machines.

- Adjustable Speed Applications – Motors with VFDs (AC induction & permanent magnet motors) allow energy-efficient speed control in HVAC systems, conveyors, and machining.

Environmental Conditions

| Environmental Condition | Recommended Motor Type | Key Considerations |

| High Temperature | TEFC (Totally Enclosed Fan-Cooled) or High-Temperature Rated Motors | Ensure proper ventilation; use high-temperature insulation and bearings. |

| Low Temperature | Low-Temperature Lubrication Motors or Arctic-Duty Motors | Use cold-weather lubricants and materials resistant to thermal contraction. |

| High Moisture / Humidity | Washdown-Rated, Stainless Steel, or IP65+ Sealed Motors | Ensure IP65+ sealing, anti-corrosion coatings, and proper drainage. |

| Exposure to Chemicals / Corrosive Substances | Chemical-Resistant, Epoxy-Coated, or Stainless Steel Motors | Use motors with chemical-resistant coatings and non-reactive materials. |

| Dusty / Dirty Environments | TEFC or Dust-Ignition Proof Motors | Prevent dust ingress using TEFC enclosures and regular cleaning schedules. |

| Explosion-Prone Areas | Explosion-Proof (XP) or ATEX-Certified Motors | Use certified explosion-proof enclosures; avoid sparking components. |

Pumps used to transfer fresh treated water to storage tanks.

What Type of Motor Should I Get For Industrial Applications

1. Conveyor Belts – AC Induction Motor with VFD

Example: A manufacturing plant requires variable-speed conveyor belts for transporting materials.

Motor Choice: AC Induction Motor (TEFC) with a Variable Frequency Drive (VFD)

Why?

- Provides smooth acceleration and deceleration to prevent product spillage.

- Energy-efficient with adjustable speed control via VFD.

- Rugged design handles continuous operation with low maintenance.

2. Overhead Cranes & Hoists – DC Motor for High Torque

Example: A steel mill needs a high-torque motor to lift heavy loads in a controlled manner.

Motor Choice: DC Motor (Shunt Wound or Compound Wound)

Why?

- Delivers instant high starting torque for lifting applications.

- Provides precise speed control for smooth, safe load handling.

- Can handle frequent reversing operations without excessive wear.

3. Robotics & Automated Machinery – Servo Motor for Precision

Example: A robotic arm in an automated assembly line requires precise motion control.

Motor Choice: Servo Motor with Closed-Loop Feedback

Why?

- Offers high-speed precision with real-time position correction.

- Allows dynamic torque adjustments, crucial for smooth robotic movement.

- High efficiency and longevity with brushless design.

4. Industrial Pumps & Fans – AC Synchronous Motor for Constant Speed

Example: A chemical plant needs consistent fluid flow in its pumping system.

Motor Choice: AC Synchronous Motor (Permanent Magnet or Electrically Excited)

Why?

- Maintains precise and constant speed, crucial for pump efficiency.

- Low-slip design improves power factor and energy savings.

- Handles continuous operation with minimal wear.

5. CNC Machines – Brushless DC (BLDC) Motor for Speed and Torque Control

Example: A CNC milling machine requires variable speed and high torque stability.

Motor Choice: Brushless DC (BLDC) Motor

Why?

- Delivers consistent torque output at varying speeds.

- Compact, high-efficiency design with low maintenance.

- Works well in precision applications requiring controlled acceleration.

6. Textile & Printing Machines – Stepper Motor for Accurate Positioning

Example: A digital textile printing press requires precise control over fabric feed.

Motor Choice: Stepper Motor with Open-Loop Control

Why?

- Provides high-accuracy positioning without needing feedback sensors.

- Works well for incremental motion control in printing and textile applications.

- Cost-effective alternative to servo motors for lower-torque applications.

Shop Our Industrial Automation & Equipment Parts Gallery

Maintenance and Safety Considerations

Proper maintenance of industrial motors ensures optimal performance, longevity, and operator safety. Regular inspections should include checking for loose connections, worn bearings, overheating, and vibration issues. Lubrication schedules must be followed for AC and DC motors, while brush inspections are crucial for brushed DC motors. For servo and stepper motors, keeping encoders and feedback systems clean is essential for precision. Safety measures include locking out power sources before servicing, using proper PPE, and ensuring enclosures meet environmental conditions. Implementing preventive maintenance programs and thermal monitoring reduces downtime, prevents failures, and extends motor lifespan in demanding industrial environments.

What Kind of Motor – Frequently Asked Questions

What are the cost implications of selecting one motor type over another?

- Initial cost vs. operational cost – While DC and servo motors may have higher upfront costs, they offer better speed control and efficiency, reducing long-term energy and maintenance expenses. AC induction motors are more affordable but may require VFDs for speed control, adding to costs.

How do I calculate the return on investment when upgrading motors?

- Consider energy savings, maintenance reductions, and productivity gains. Use the formula:

ROI (%) = [(Energy & Maintenance Savings – Upgrade Cost) / Upgrade Cost] × 100 - High-efficiency motors (IE3, IE4) often pay for themselves through lower power consumption.

- Consider energy savings, maintenance reductions, and productivity gains. Use the formula:

What are the signs a motor needs maintenance or replacement?

- Excessive heat or vibration

- Unusual noises (grinding, whining, or clicking)

- Frequent tripping of circuit breakers

- Decreased efficiency or inconsistent performance

- Burnt odor or visible wear on components

How does motor efficiency impact overall industrial productivity?

- Higher efficiency = lower energy costs and reduced heat generation. This leads to less downtime, longer equipment lifespan, and improved system performance. Motors with high-efficiency ratings (IE3, IE4, NEMA Premium) contribute to sustainable operations.

Can I use a standard AC motor in a high-moisture environment?

- Not recommended. Standard motors can suffer from corrosion, insulation failure, and electrical shorts. Instead, use washdown-rated, stainless steel, or IP65+ enclosed motors for wet or humid conditions.

What are the specific advantages of brushless DC motors in industrial applications?

- Higher efficiency and longer lifespan (no brushes = less wear).

- Better speed and torque control, ideal for robotics and automation.

- Lower maintenance compared to brushed DC motors.

- Compact size with high power output, perfect for space-constrained applications.