At TCI Supply, we specialize in providing high-quality industrial and commercial circuit boards designed for various applications, including automation, power control, and system integration. Our range of circuit boards is sourced from trusted brands such as Siemens, Honeywell, Allen Bradley, ABB, Schneider Electric and more, ensuring reliability and durability in challenging environments.

At TCI Supply, we specialize in providing high-quality industrial and commercial circuit boards designed for various applications, including automation, power control, and system integration. Our range of circuit boards is sourced from trusted brands such as Siemens, Honeywell, Allen Bradley, ABB, Schneider Electric and more, ensuring reliability and durability in challenging environments.

GE circuit boards are integral components used in various industrial and commercial applications. They are found in equipment like motor control systems, automation panels, and power distribution units, providing essential control and functionality. GE circuit boards are engineered to meet high-quality standards, making them suitable for use in environments where performance, reliability, and safety are crucial, such as manufacturing plants, HVAC systems, and power generation facilities.

Yes, TCI Supply Stocks and procures leading manufacturers like Siemens and Honeywell to offer customized circuit board solutions that align with your specific operational needs. Consider replacing the board instead of the entire component to save time and money.

Circuit boards, especially those from brands like Siemens, are designed to withstand extreme temperatures and high humidity levels, making them ideal for demanding industrial environments.

Industrial circuit boards are designed to handle extreme environmental conditions. Typical operating ranges are between -40°C to +85°C (-40°F to +185°F). Some high-reliability boards can operate at temperatures up to +125°C (257°F) or higher for specialized applications.

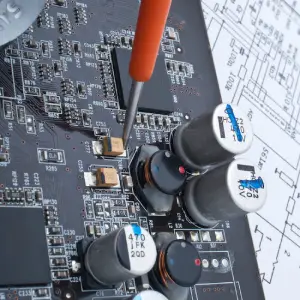

Regular inspections and timely replacement of components, especially in boards used in high-stress environments, are crucial for maintaining optimal performance. We recommend using boards from brands known for their durability, such as Allen Bradley.

Circuit boards, particularly those from Honeywell and Allen Bradley, are engineered with advanced EMI shielding, conformal coating, to minimize interference, ensuring stable operation in electromagnetically noisy environments.

Allen Bradley & GE circuit boards handle electromagnetic interference (EMI) through various methods, including shielding and grounding to protect sensitive components, and the use of filtering components like capacitors and inductors to reduce noise. The boards are designed with optimized trace layouts to minimize interference, ensuring separation of high-frequency and sensitive circuits. Additionally, most of our products comply with EMI/EMC standards such as CE and FCC, providing reliable performance even in environments with high levels of electromagnetic interference.

Our boards are designed for seamless integration with existing systems, leveraging industry-standard protocols and compatibility with various automation systems, such as those from Siemens. Not all boards have backwards compatible series, check the technical details for your board before replacing.

To integrate industrial circuit boards (e.g., GE, Siemens, Trane, Allen-Bradley) with existing systems, start by ensuring communication protocol, voltage, and I/O compatibility. Use gateways if protocols differ and configure PLCs, HMIs, or SCADA systems for communication. Set up proper network configurations, including IP addresses and cybersecurity measures. Test and validate integration with simulations and load testing, and update all documentation for compliance and maintenance. Lastly, train personnel on system operations and schedule routine maintenance to ensure long-term performance and efficiency in the integrated setup.

Yes, TCI Supply offers circuit boards from brands like Siemens and Honeywell, designed and built with robust materials and advanced protective coatings to withstand extreme temperatures, moisture, dust, and vibration. They are ideal for use in applications like mining, oil and gas, and heavy industrial settings. GE’s rugged circuit boards feature enhanced insulation and shielding to ensure stable operation, reducing the risk of failure and extending the lifespan of critical control systems in demanding industrial environments.

Please contact your sales representative today.

Fill in the form below, or call us now at 1-800-755-2883

"*" indicates required fields

©2024 TCI Supply. All Rights Reserved. 611 Morgan Ave. Drexel Hill, PA 19026