What Is a Control System: Automation and Applications

Types of Control Systems

Implementing Automated Control Systems

Manual Process vs Automated Process

Benefits of Automating Manual Processes

Steps to Automate a Control System

Control System Definition – Frequently Asked Questions

A control system is a framework designed to manage, command, regulate, or direct the behavior of other systems to achieve desired outcomes. It typically consists of three basic components: sensors, controllers, and actuators. Sensors monitor the system and provide real-time data, such as temperature, pressure, or position, which is crucial for understanding the system’s current state. Controllers process this data and make decisions based on a set of programmed rules or algorithms, ensuring the system operates within its desired parameters. Actuators execute these decisions by physically altering the system, such as opening a valve, starting a motor, or moving a mechanism.

Control systems can be classified into two types: open-loop and closed-loop. In an open-loop system, actions are performed without feedback; the system does not monitor or adjust its operation based on outcomes, making it simpler but prone to errors if conditions change. Closed-loop systems, also known as feedback systems, continuously monitor the output through sensors and adjust actions to minimize deviations from the desired setpoint. This feedback loop ensures greater accuracy and stability, commonly seen in thermostats, autopilot systems, and industrial automation. Together, sensors, controllers, and actuators work harmoniously to maintain system functionality and efficiency, whether in simple open-loop designs or more sophisticated closed-loop configurations.

Shop Our Industrial and Commercial Actuators

Types of Control Systems

| Control System | Role | Functionalities | Major Brands | Average Cost |

|---|---|---|---|---|

| PLC (Programmable Logic Controller) | Used for automation of industrial processes, machine control, and real-time control applications. | Fast, real-time control of machinery; modular and scalable; primarily used for discrete manufacturing processes. | Allen Bradley (Rockwell), Siemens, Mitsubishi, Schneider Electric, ABB | $5,000 – $50,000 (depending on size and complexity) |

| DCS (Distributed Control System) | Manages large, complex processes across multiple locations; integrates control and monitoring of systems. | Centralized control for continuous processes; integrates with multiple PLCs; provides redundancy and reliability. | Honeywell, Emerson, Yokogawa, Siemens, ABB | $100,000 – $1,000,000+ (for large, continuous operations) |

| SCADA (Supervisory Control and Data Acquisition) | Provides a central platform to monitor and control large-scale systems remotely, combining data collection and supervisory control. | Monitors and controls geographically distributed assets; enables data collection, visualization, and remote supervisory control. | GE Digital, Siemens WinCC, Rockwell Automation | $20,000 – $500,000+ (based on system scale and licenses) |

Shop Our Industrial and Commercial PLCs

Implementing Automated Control Systems

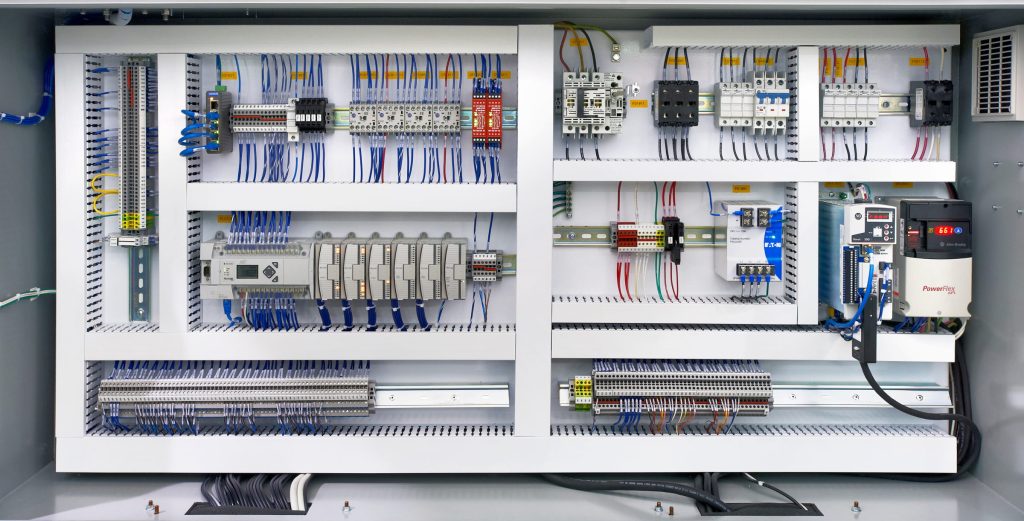

- Programmable Logic Controllers (PLCs):

- PLCs are ruggedized computers designed for real-time control of machinery and processes.

- They use inputs (sensors, switches) to make decisions based on preprogrammed logic and control outputs (motors, actuators).

- Technologies like ladder logic, structured text, and function block diagrams facilitate ease of programming and modification.

- Integration: PLCs connect with SCADA systems, DCS, and other networks via communication protocols like Modbus, Ethernet/IP, and PROFINET.

- Distributed Control Systems (DCS):

- DCSs automate large-scale, continuous processes such as chemical plants and power generation.

- They integrate with PLCs and field devices to centralize monitoring and control, ensuring real-time operation and high reliability.

- Redundant architectures and advanced communication protocols like FOUNDATION Fieldbus and HART ensure minimal downtime.

- Integration: Seamlessly connects with SCADA systems for higher-level supervisory control.

- Supervisory Control and Data Acquisition (SCADA):

- SCADA systems enable remote monitoring and supervisory control of distributed assets like pipelines, water systems, and power grids.

- Technologies such as RTUs (Remote Terminal Units) and Human Machine Interfaces (HMIs) collect, process, and visualize real-time data.

- Integration: SCADA systems connect with PLCs, DCSs, and IoT sensors through protocols like MQTT, OPC UA, and DNP3.

- Human Machine Interfaces (HMIs):

- HMIs provide graphical interfaces for operators to monitor processes and input commands in real time.

- Modern HMIs support touchscreens and mobile access, improving ease of use.

- Integration: HMIs interface directly with PLCs, SCADA, and DCS platforms for seamless operation.

- Industrial Internet of Things (IIoT):

- IIoT technologies leverage sensors, edge devices, and cloud platforms to collect and analyze real-time data.

- Predictive maintenance, anomaly detection, and performance optimization are achieved using advanced analytics and AI.

- Integration: IIoT platforms connect with control systems using protocols like MQTT, OPC UA, and Edge Gateway technology.

Shop Our Industrial and Commercial Sensors

Manual Process vs Automated Process

| Aspect | Manual Process Control | Automated Process Control |

|---|---|---|

| Speed | Slower response time due to human intervention. | Extremely fast response time with real-time operation. |

| Accuracy | Prone to human error, leading to inconsistencies. | High accuracy with precise, programmed instructions. |

| Reliability | Depends on operator skill and attentiveness. | Highly reliable with redundancy and fail-safe systems. |

| Consistency | May vary due to fatigue, distraction, or human factors. | Consistent output regardless of external conditions. |

| Cost | Lower upfront cost but higher long-term labor expenses. | Higher upfront cost but lower operating costs over time. |

| Scalability | Limited; difficult to scale efficiently. | Highly scalable with modular and programmable systems. |

| Monitoring | Limited to what operators can observe manually. | Continuous, real-time monitoring and data collection. |

| Decision-Making | Relies on operator judgment, which may delay actions. | Instantaneous, based on programmed logic or AI. |

| Data Collection | Manual and incomplete; subject to errors. | Automated, comprehensive, and precise. |

| Safety | Higher risk of accidents due to human error. | Enhanced safety with sensors, alarms, and safety logic. |

| Maintenance | Reactive; depends on operator awareness. | Proactive with predictive maintenance capabilities. |

Shop Our Industrial Processors

Benefits of Automating Manual Processes

- Reduced Errors:

Automation minimizes human errors caused by fatigue, distraction, or misjudgment. Systems follow pre-programmed logic, ensuring accuracy and repeatability. - Increased Safety:

Automation reduces the need for human presence in hazardous environments (e.g., high temperatures, toxic areas). Safety interlocks, alarms, and emergency shutdown systems enhance protection. - Improved System Responsiveness:

Automated systems react instantly to changes in inputs, ensuring real-time control. Fast decision-making improves efficiency and reduces delays in processes. - Higher Accuracy and Precision:

Automation enables precise control of variables like temperature, pressure, and flow rates. Systems consistently meet tight tolerances and quality standards. - Enhanced Reliability and Consistency:

Automated systems operate consistently, unaffected by operator fatigue or human factors. This leads to uniform outputs and predictable performance. - Cost Savings Over Time:

Automation reduces long-term labor costs and production downtime. Improved process efficiency leads to better resource utilization and savings. - Real-Time Monitoring and Data Collection:

Automated systems collect and analyze real-time data, improving decision-making. Continuous monitoring enables proactive maintenance and performance optimization. - Increased Productivity:

Automation allows processes to run continuously without breaks or delays. Machines can operate at higher speeds and handle more tasks simultaneously. - Scalability:

Automated systems are modular and scalable, making it easier to expand or adapt processes. Adding or modifying control logic is faster and more cost-effective than training personnel. - Improved Maintenance Capabilities:

Automation enables predictive maintenance through data-driven insights and AI. Early detection of faults reduces unplanned downtime and repair costs. - Better Resource Management:

Optimized control of processes reduces waste of energy, materials, and time. Automation helps achieve sustainability and efficiency goals.

Shop Our Industrial Control Manufacturers and Suppliers

Steps to Automate a Control System

1. Initial Assessment and Feasibility Study

- Evaluate Current Processes:

Analyze existing manual processes to identify areas that can benefit from automation. Focus on repetitive, time-consuming, or error-prone tasks. - Determine Goals and Objectives:

Define key objectives such as improving accuracy, reducing costs, increasing safety, or enhancing efficiency. - Conduct Feasibility Analysis:

Assess technical and financial feasibility. Budget requirements, ROI (Return on Investment), and available resources. Evaluate the infrastructure readiness for automation. - Engage Stakeholders:

Include operators, managers, engineers, and IT teams to ensure alignment on project goals.

2. Detailed Planning and Design

- Select the Right Technology:

Determine which control systems are suitable: PLCs, DCS, SCADA, or IIoT solutions. Identify appropriate hardware (e.g., sensors, controllers, actuators) and software (e.g., HMI, programming tools). - Define System Requirements:

Document control parameters, speed, accuracy, safety protocols, and redundancy needs. - Create an Implementation Roadmap:

Outline the timeline, milestones, and phases of the transition. Start with small-scale pilots or phased implementation for large systems. - Prepare Risk Assessment:

Identify potential challenges and plan mitigation strategies, such as system downtime or training issues.

3. System Procurement and Integration

- Acquire Equipment and Software:

Purchase automation hardware, software, and communication infrastructure. - System Configuration and Integration:

Set up PLCs, SCADA systems, or DCS controllers to interface with existing processes. Integrate sensors, actuators, and human-machine interfaces (HMI) for real-time control. Ensure communication networks (e.g., Ethernet/IP, Modbus, PROFINET) are in place. - Data Migration:

Transition critical process data from manual logs or systems to automated platforms for accurate operation.

4. Implementation

- Install Hardware and Software:

Set up physical devices (PLCs, sensors, HMIs, SCADA components) and configure the control logic/programming. - Conduct Initial Testing (Bench Testing):

Verify all components and software in isolation before full integration. - Pilot Testing:

Implement the automated system on a small scale or single process line. Identify and address any issues before full-scale deployment.

5. Training and Change Management

- Operator Training:

Train employees on how to operate, monitor, and maintain the new automated system. Include HMI usage, emergency protocols, and troubleshooting techniques. - Management of Change:

Address resistance by demonstrating benefits such as improved efficiency, reduced workload, and enhanced safety. - Develop Documentation:

Provide manuals, standard operating procedures (SOPs), and system architecture documentation.

6. System Testing and Validation

- Full-Scale Testing:

Run the automated system under actual operating conditions to ensure it meets performance criteria. - Performance Validation:

Verify:- Speed, accuracy, and reliability.

- Safety interlocks and fail-safe mechanisms.

- Data collection, reporting, and integration with other systems.

- Fine-Tuning:

Adjust parameters, optimize control logic, and resolve any discrepancies identified during testing.

7. Monitoring and Continuous Improvement

- System Monitoring:

Use real-time data monitoring tools to evaluate performance, efficiency, and output quality. - Collect Feedback:

Gather operator and stakeholder input to identify areas for improvement. - Optimize Processes:

Implement updates, new features, or performance improvements based on ongoing analysis. - Regular Maintenance and Upgrades:

Schedule preventive maintenance, firmware/software updates, and periodic inspections to ensure system longevity.

8. Review and Scale-Up

- Measure Results:

Compare system performance against initial goals (e.g., cost savings, accuracy improvements). - Evaluate ROI:

Analyze return on investment and financial benefits from automation. - Plan for Expansion:

Scale the automated system to other processes, departments, or facilities based on success metrics.

Shop Our Industrial Automation & Equipment Parts Gallery

Control System Definition – Frequently Asked Questions

- What defines an automatic process control? An automatic process control uses sensors, controllers, and actuators to manage and regulate processes without human intervention. It ensures processes run smoothly, efficiently, and consistently by automatically adjusting system parameters in real time.

- What are the major differences between open-loop and closed-loop systems? An open-loop system has no feedback; the system performs a task based on preset conditions. A Closed-loop system uses feedback to monitor and adjust the system continuously.

- How do PLCs contribute to automated control systems? PLCs provide real-time control of machines and processes. They offer flexibility with easy programming, fast processing, and modular designs. They interface with sensors, actuators, and HMIs to automate tasks and ensure precision.

- What are the challenges in automating an existing manual control system? High initial cost, System Downtime, Integration issues, Training Needs, and Internal Resistance to Change

- How does automation impact system efficiency and error rates? It should increase efficiency due to faster response times and continuous operation. It should drastically reduce error rates as there is little human error