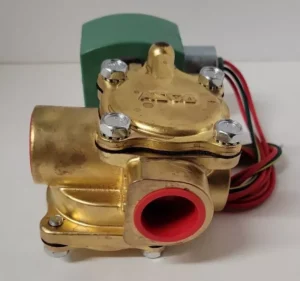

The Asco 8316G046 Solenoid Valve (8316G46) is a 3-way, normally open, pilot-operated valve specifically designed for air, water, and inert gas control. Its diaphragm poppet and high-pressure capability (up to 250 psi) ensure reliable fluid management, ideal for demanding applications like high-pressure pumps, commercial laundry systems, car wash equipment, and industrial air compressors.

Technical Specifications

- Valve Type: 3-way, Normally Open, Pilot Operated

- Pipe Size: 3/4″ NPT

- Flow Factor (Cv): 4.8

- Operating Pressure Differential:

- Air/Inert Gas: 10 to 250 psi (AC), 10 to 250 psi (DC)

- Water: 10 to 250 psi (AC), 10 to 250 psi (DC)

- Maximum Fluid Temperature:

- AC: 180°F (82°C)

- DC: 120°F (49°C)

- Body Material: Brass

- Seal Material: NBR

- Voltage Options:

- AC (60Hz): 24, 120, 240, 480V

- AC (50Hz): 110, 220V

- DC: 6, 12, 24, 120V

- Watt Rating:

- AC: 17.1 watts

- DC: 22.6 watts

- Coil Insulation Class: F

- Solenoid Enclosure:

- Standard: NEMA 4X, IP65 (Watertight, Corrosion-Resistant)

- Optional: Explosionproof & Watertight (Types 3-9), Raintight (Types 3, 7, 9)

Key Features and Functionality

- Precision Fluid Control: Accurate regulation through a responsive diaphragm poppet.

- Enhanced Flow Capacity: The Internal pilot mechanism supports large orifices.

- Actuator Efficiency: Effective piloting for rapid valve actuation.

- Flexible Orientation: Installation versatility for diverse setups.

- Durable Sealing System: Long-term leak prevention and reliability.

Compatible Components and Related Parts

- ASCO RedHat II Coil Series

- ASCO Mounting Brackets

- ASCO Seal Kit for 8316 Series

- ASCO Explosionproof Solenoid Enclosure

Industry Applications

- Laundry Equipment: Precision water flow control.

- Industrial Air Systems: Reliable and stable air handling.

- Pumps: Accurate fluid flow and actuator piloting.

- Vehicle Wash Stations: Durable control in frequent-use environments.

- Water Management Systems: Consistent fluid regulation in commercial settings.

Compliance and Approvals

- CSA Certified

- CE Compliant

- ATEX/IECEx Certified (with EV prefix)

Installation and Operational Notes

- Confirm adequate pressure differential is maintained between ports for optimal function.

- Avoid restrictions by ensuring supply and exhaust lines have unrestricted, full-area piping.

- Flow control devices or similar restrictions must be installed only downstream in cylinder lines.

- Check media compatibility and temperature ratings before valve installation.

- Perform routine maintenance checks and replace seals promptly with ASCO OEM parts.

We ship this product worldwide! Delivery is normally stock.

Request a Quote now or call us at 1-800-755-2883 for expert assistance.