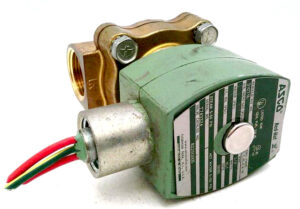

The Asco 8220G005 Solenoid Valve (8220G5) is a pilot-operated, normally closed valve engineered for precision in high-temperature water and steam systems. Its 3/4″ configuration, EPDM or PTFE options, and sturdy brass housing make it suitable for heavy-duty cycles in food equipment, sterilizers, and boiler systems that require elevated fluid temperatures.

Technical Specifications

- Valve Type: Pilot Operated, Normally Closed, 2-Way

- Pipe Size: 3/4″ NPT

- Flow Factor (Cv): 5.0

- Operating Pressure Differential:

- Steam: 5 to 50 psi

- Hot Water: 5 to 150 psi

- Maximum Fluid Temperature:

- Steam: 300°F (149°C)

- Hot Water: 210°F (99°C)

- Body Material: Brass

- Seal Material: EPDM or PTFE

- Voltage Options:

- AC: 24, 120, 240, 480 V

- DC: 6, 12, 24, 120, 240 V

- Watt Rating:

- AC: 10.1 watts

- Coil Insulation Class: F

- Solenoid Enclosure:

- Standard: RedHat II – Watertight, Types 1, 2, 3, 3S, 4, and 4X

- Optional: Explosionproof & Watertight, Types 3, 3S, 4, 4X, 6, 6P, 7, and 9

Key Features and Functionality

- Reliable Steam Control: Designed for continuous heat exposure.

- Sturdy Seal Disc: Minimizes wear from temperature swings.

- High Flow Output: 5.0 Cv supports larger water loads.

- Efficient Energy Use: Draws only 10.1 watts during operation.

- Brass Body Housing: Provides corrosion resistance and strength.

Compatible Components and Related Parts

- ASCO RedHat II Coil Series

- ASCO Mounting Brackets

- ASCO Seal Kit for 8220 Series

- ASCO Explosionproof Solenoid Enclosure

Industry Applications

- Boiler Rooms: Supports steam flow management.

- Dishwasher Equipment: Ensure that hot rinse cycles are well-managed

- Food Equipment: Controls high-temp water in cooking systems.

- Hospital Sterilizers: Maintains sanitation-grade steam lines.

- Laundry Heating Systems: Operates under wet heat cycles.

Compliance and Approvals

- UL Listed

- CSA Certified

- Meets Applicable CE Directives

Installation and Operational Notes

- Verify that the solenoid coil voltage exactly matches the system power.

- Depressurize the system and clean all internal piping before installation.

- Install a strainer or filter at the valve inlet as close as possible.

- Do not overtighten or allow piping to place stress on the valve body.

- Energize the coil a few times after wiring to confirm actuation by an audible click.

Series Catalog

Asco Hot Water and Steam Valves Two Way

We ship these products worldwide! Delivery is normally stock.

Request a Quote now or call us at 1-800-755-2883 for expert assistance.